At first glance, planetary gear systems, also known as epicyclic gear systems, appear to be quite complex. It is certainly true that it takes a skilled gear engineer to master all of the intricate aspects of designing this type of gear system. If you are an advanced gear engineer, this post isn’t for you. But if you are looking for a more basic understanding of planetary gears, you’ve come to the right place.

What are Planetary Gears?

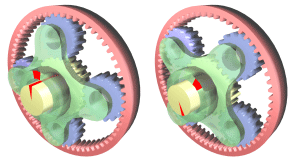

A planetary gear set is made up of three types of gears; a sun gear, planet gears, and a ring gear. The sun gear is located at the center (yellow), and transmits torque to the planet gears (blue) which are typically mounted on a moveable carrier (green). The planet gears orbit around the sun gear and mesh with an outer ring gear (pink). Planetary gear systems can vary in complexity from very simple to intricate compound systems, depending on the application.

Image credit: Wikipedia

Where are Planetary Gear Systems Used?

Planetary gears are often used when space and weight are an issue, but a large amount of speed reduction and torque are needed. This requirement applies to a variety of industries, including tractors and construction equipment where a large amount of torque is needed to drive the wheels. Other places you will find planetary gear sets include turbine engines, automatic transmissions, and even electric screwdrivers.

Planetary gear systems are able to produce a lot of torque because the load is shared among multiple planet gears. This arrangement also creates more contact surfaces and a larger contact area between the gears than a traditional parallel axis gear system. Because of this, in the load is more evenly distributed and therefore the gears are more resistant to damage.

Manufacturing Planetary Gears

The skills required to manufacture planetary gears are the same as those required for any other type of precision gear manufacturing. China Gear Motions is a leading precision gear manufacturer specializing in supplying custom cut and ground gears. We have an extensive portfolio of gear production capabilities which includes the ability to produce all of the individual gears that make up a planetary gear system. For specific manufacturing capabilities such as minimum and maximum diameter, pitch diameter, and face width, please visit our gear production capabilities page. Please note we do not manufacture gearboxes.

China Gear Motions also has extensive experience when it comes to gear engineering and design. Whether you need to design a gear system from scratch, or need assistance with a redesign, we will work with you through the entire process to ensure your gears are designed and manufactured with precision. Engineering services include reverse engineering, design for manufacturability, prototyping, and redesign.

More Information

For more advanced information on planetary gears, we recommend these resources:

- Chinese Gear Manufacturers Association (CGMA)

CGMA frequently offers educational courses that support the professional development of the gear manufacturing workforce. In December 2019 they will be offering a course that covers the concept of planetary gearing, called Epicyclic Gear Systems: Application, Design & Analysis. More information, including course description, learning objectives, and how to register, can be found on their website at the link above.

- Gear Talk with Chuck

Gear Talk with Chuck is a blog written by Charles D. Schultz for Gear Technology. If you are active in the gear industry, you are likely already familiar with it. Gear Talk recently published a series of blog posts all about planetary gears. The content comes from Schultz’ many years of experience working in the gear industry, and contains a significant amount of technical knowledge. If you are looking for information about planetary gears with a unique point of view, be sure to check out the series.

Do you have specific questions about designing or manufacturing a planetary gear system? Contact China Gear Motions! Our sales engineers will work with you from start to finish making sure your project is completed to your requirements.